Installation Guidelines

Read and follow the engineer’s specifications for materials and installation. All safety regulations must be enforced. All installation of vitrified clay pipe lines should follow ASTM C12 Standard Practice for Installing Vitrified Clay Pipe Lines.

1

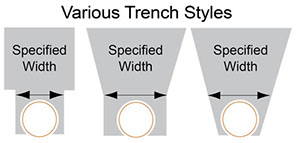

The trench width at the top of the pipe should not exceed the specification. (The specification must allow adequate room for shovel slicing the haunches.) An increase in the trench width may create an overload on the pipe.

2

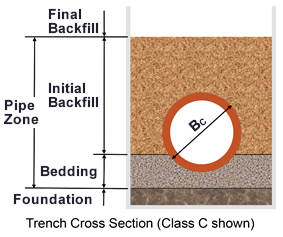

The foundation must be firm and unyielding before bedding placement. Keep water out of the trench bottom. Where the trench bottom is soft and unsuitable to support the pipe, bedding and backfill, removal and replacement of foundation material is necessary. Consult the design engineer or a geotechnical engineer to ensure the foundation can support the load.

Heading Text

3

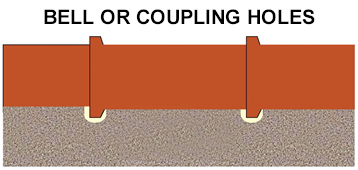

Dig bell or coupling holes before pipe is laid ensuring the bells or couplings support no part of the load.

4

Clean bell and spigot, including the O-Ring groove. Equalize the tension in the O-Ring by running a screwdriver or smooth tool completely around the spigot, under the O-Ring.

Clean bell and spigot, including the O-Ring groove. Equalize the tension in the O-Ring by running a screwdriver or smooth tool completely around the spigot, under the O-Ring.

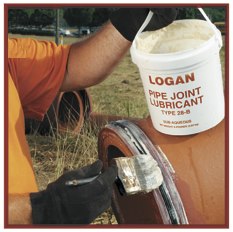

Lubricate both the spigot and the socket ends liberally to allow pipe to slide home. Make sure the gasket is in place by running your fingers completely around the assembled joint.

Lubricate both the spigot and the socket ends liberally to allow pipe to slide home. Make sure the gasket is in place by running your fingers completely around the assembled joint.

When working in cold weather, it is recommended that O-Ring gaskets be stored inside vehicles or construction offices until they are needed to assure ease of installation.

5

Pipe sections must be in straight alignment prior to homing. If a bar is used to shove the pipe home, use a block of wood to cushion the bell.

6

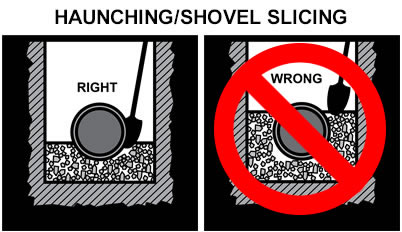

Shovel slicing must be done before the bedding is no higher than the quarter point of the pipe, it helps create uniform circumferential support of the pipe barrel.

Shovel-slice bedding material into the pipe haunches for the entire length of the pipe barrel to ensure uniform support. Do not shovel slice under the bell.

7

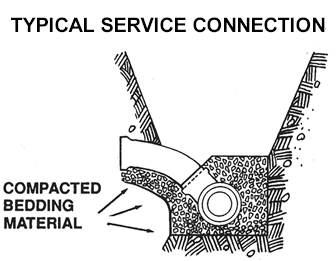

Make sure the fittings, stubs and risers are well-supported. Tamp or shovel slice bedding into the haunches of the pipe and fittings.

8

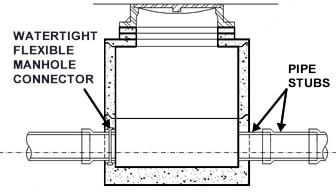

Two points of flexibility should be used within 36 in. of each manhole connection. This can be accomplished by using:

- two short lengths (stubs of 24 in. or less) OR

- one short length and one flexible manhole connector.

9

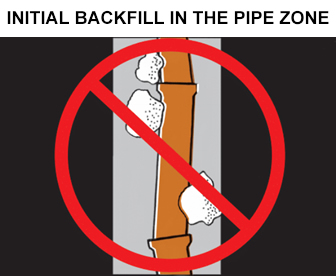

Do not let rocks or large dirt clods in the pipe zone. They can damage the pipe and alter the alignment.

10

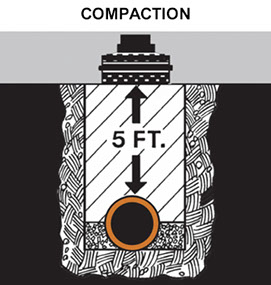

Suitable compaction equipment must be selected with care. A falling weight “stomper” or drop hammer should never be used. Walk behind and handheld light compaction equipment can be used within the trench and at cover depths of less than 5 feet.

Extreme care should be taken when using heavy mechanical compaction equipment. A minimum of 5 feet of cover over the top of the pipe is required before any heavy mechanical compaction equipment is used.

11

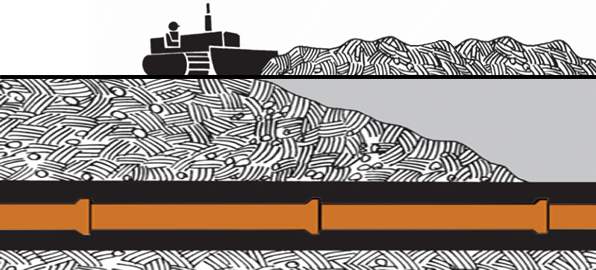

Place the final backfill into the trench at an angle. This keeps impact on the installed line to a minimum.