Logan’s O-Ring Joint

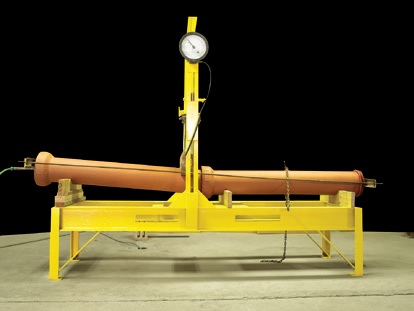

Field Tested – Field Proven

The clay pipe sewers installed early in our nation’s history were not supplied with a joint. The installers joined pipe by applying tar or mortar in the trench. These joints allowed significant infiltration which was beneficial as it diluted the effluent and cleaned the lines. These sewers generally discharged into waterways without treatment.

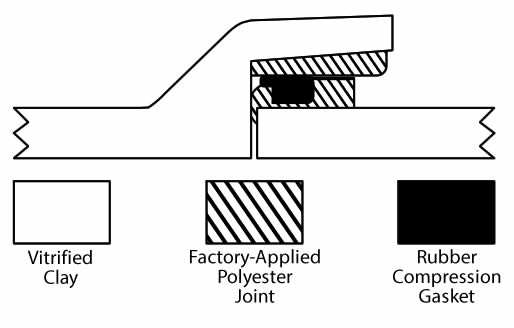

As cities began treating sewage, infiltration became an expense. Logan Clay responded by introducing factory applied joints. Each generation of factory applied joints improved upon the last until the O-ring joint was developed achieving the leak-free performance that communities needed.

The Logan O-Ring joint has proven to be a reliable, water tight joint for more than 50-years. When installed in accordance with ASTM C12 specifications, our pipe and O-Ring joints eliminate the infiltration that was prevalent in early clay pipe lines.

Deflection Allowed by ASTM C425

| Nominal Diameter | Deflection of Pipe |

|---|---|

| 4-12″ (101-305 mm), inclusive | 1/2″ (42 mm) |

| 15-24″ (381-610 mm), inclusive | 3/8″ (31 mm) |

The Logan O-Ring joint meets or exceeds ASTM C425.

Product Types

Logan’s O-Ring Joint

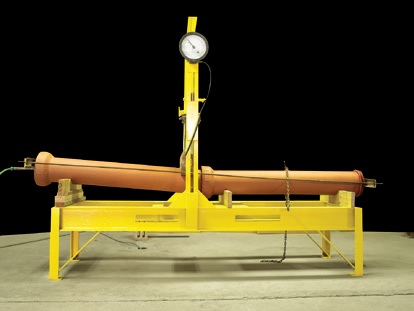

Field Tested – Field Proven

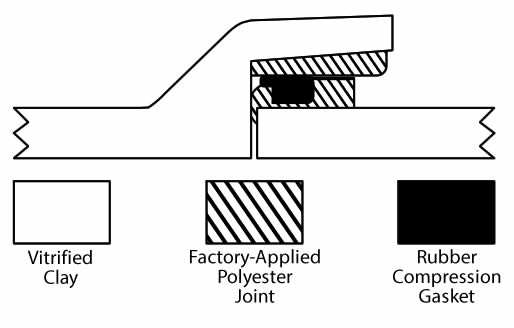

The clay pipe sewers installed early in our nation’s history were not supplied with a joint. The installers joined pipe by applying tar or mortar in the trench. These joints allowed significant infiltration which was beneficial as it diluted the effluent and cleaned the lines. These sewers generally discharged into waterways without treatment.

As cities began treating sewage, infiltration became an expense. Logan Clay responded by introducing factory applied joints. Each generation of factory applied joints improved upon the last until the O-ring joint was developed achieving the leak-free performance that communities needed.

The Logan O-Ring joint has proven to be a reliable, water tight joint for more than 50-years. When installed in accordance with ASTM C12 specifications, our pipe and O-Ring joints eliminate the infiltration that was prevalent in early clay pipe lines.

Deflection Allowed by ASTM C425

| Nominal Diameter | Deflection of Pipe |

|---|---|

| 4-12″ (101-305 mm), inclusive | 1/2″ (42 mm) |

| 15-24″ (381-610 mm), inclusive | 3/8″ (31 mm) |

The Logan O-Ring joint meets or exceeds ASTM C425.